Nickel is found in the earth’s crust in ultramafic rocks and also in iron-nickel meteorites. Commercially important ores of nickel are pentlandite and garnierite.Many of you may wonder whether Nickel undergoes rusting or not. In this article, we will study the same and will also cover its related topics.So, does Nickel rust? No, Nickel does not rust because rusting is the property of iron and relative alloys that form a layer of iron oxide on the outer surface owing to oxidation. Other metals may undergo corrosion upon exposure to a harsh environment due to oxidation. However, Nickel is highly resistant to corrosion for a wide range of atmospheric conditions but corrodes when exposed to severe atmospheric conditions for a long duration.

Is Nickel Corrosion Resistant?

Yes, Nickel is the most corrosion-resistant metal known. Pure Nickel can withstand high temperatures, a variety of chemicals, excessive humidity, and other extreme conditions. Being highly resistant to corrosion, Nickel is used in manufacturing many items meant to be used in severe environments.These environments include chemical reactors, where they encounter several harsh chemicals, or ships and boats, which have to endure a wide range of weather conditions.The corrosion-resistance property of nickel makes it suitable for making an extensive number of alloys such as wrought nickel, nickel-iron, nickel-chromium, and nickel-copper alloys, etc.These alloys are capable of tolerating extreme conditions and are incredibly resistant to corrosion. The percentage of nickel also varies in different alloys depending upon the use for which it is being manufactured.The combination of nickel with different metals imparts different properties to the alloys, for example, with chromium the alloys are more resistant to oxidizing corrosives and high temperatures while with iron the alloys show better resistance towards carburizing environments.Nickel especially reduces the rate of propagation of pitting and crevice corrosion. In alloys such as stainless steel, Nickel is especially useful in resisting chloride stress-corrosion cracking.However, we must understand that Nickel is corrosion-resistant and not corrosion-proof. Therefore, when exposed to extreme conditions for a long duration, Nickel may also undergo corrosion forming a nickel oxide layer.

Difference Between Corrosion and Rusting

Both rusting and corrosion occur due to oxidation of the material, especially metals. However, unlike rusting corrosion is not always a bad thing.Few differences between rusting and corrosion are given below.• Rusting is a chemical process while corrosion is an electrochemical process.• Rusting only occurs in the case of iron and its alloys while corrosion may occur in other metals, or wood, or even your skin (Remember some acids are known to be corrosive for skin).• Rusting makes a substance brittle and fragile as it results in the formation of a loose powdery layer of iron oxide that exposes internal material for further damage.On the other hand, corrosion makes the material more stable due to forming an outer layer of oxide that covers and protects the material underneath it from further damage.

Why is Nickel Corrosion Resistant?

The corrosion resistance of Nickel is majorly due to its crystal lattice structure.The austenitic structure or face-centered cubic lattice makes Nickel an extremely tough and ductile material. It has the lattice parameter of 0.352 nm and an atomic radius of 0.124 nm.This crystal structure can withstand pressure as high as 70 GPa indicating that Nickel is a very strong material.This also makes the articles made of nickel and its alloys exceptionally durable, efficient, and corrosion-resistant.

Can Nickel Oxidize?

Yes, Nickel slowly oxidizes at room temperature in the presence of air.The electronic configuration of Nickel is disputed and it is known to exist as [Ar] 3d8 4s2 and [Ar] 3d9 4s1. Hence, it is known to exist in many oxidation states viz. +1, +2, +3 and +4.Pure Nickel reacts with oxygen at a temperature above 800 °C and forms Nickel Oxide as per the following reaction:2Ni + O₂ —–> 2NiOAlso, powdered form of nickel is known to ignite spontaneously in the presence of air as mentioned in the chemical equation below:5Ni + 3O₂ —-> 3NiO + Ni₂O₃Other compounds in which Nickel is present in several oxidation states are Carbonyl Ni(CO)4, Nickel nitride Ni3N2, Nickel sulfate NiS, etc.

Does Nickel Turn Green?

Nickel also undergoes corrosion when left in acute environmental conditions for a protracted duration.The reaction of Nickel with oxygen and humidity under high temperatures, excessive acidity or alkalinity, or other severe settings results in the formation of a layer of nickel oxide on the outer surface of the metal.This layer is initially reddish but slowly turns greenish over time and is referred to as patina.Patina forms a protective covering around the surface of Nickel and does not let oxygen or moisture affect the internal layers, thus, preventing further corrosion.Therefore, patina adds to the stability and durability of Nickel by making it resistant to further damage.

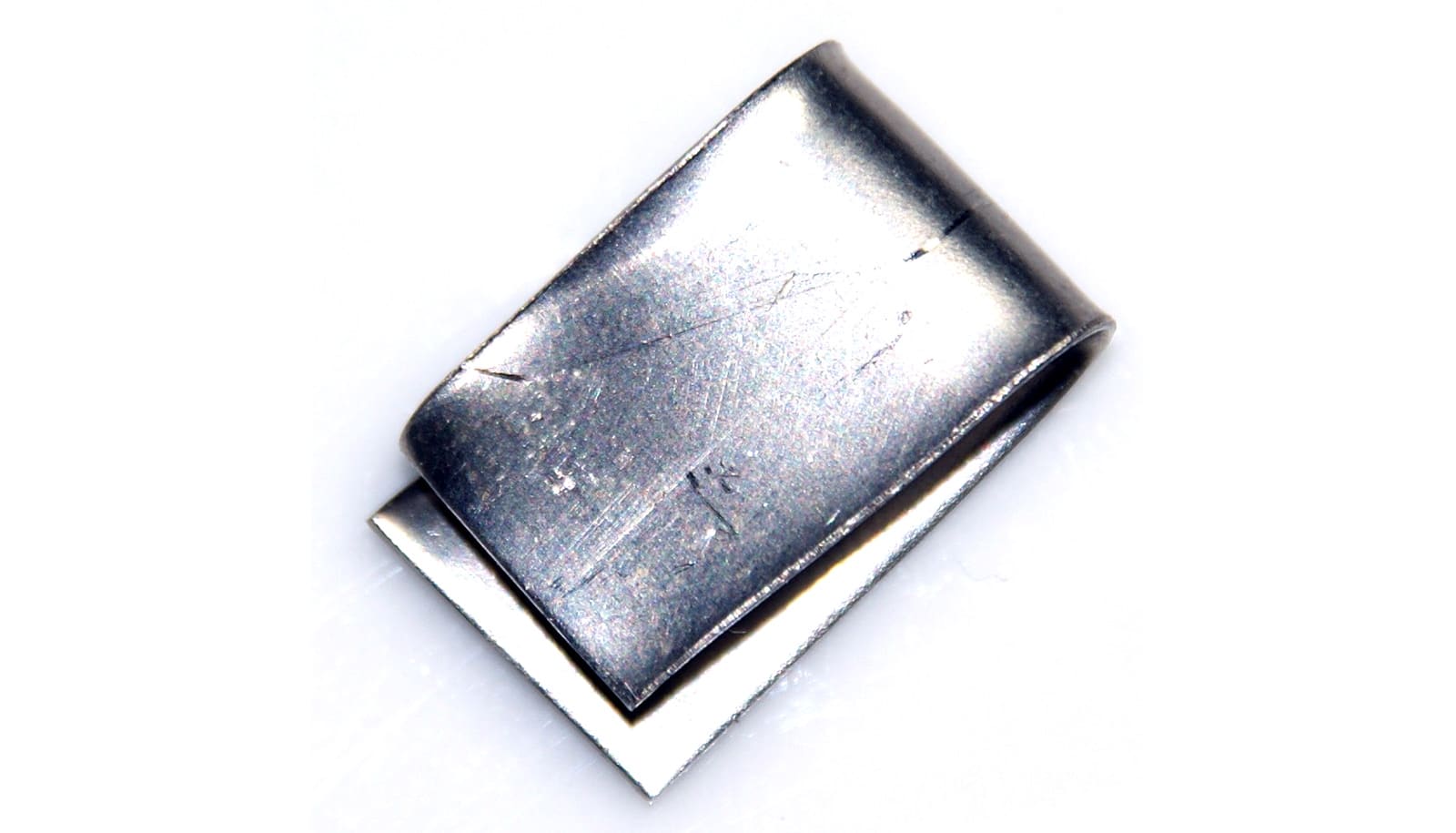

What is Nickel Plating?

Nickel plating is a technique in which a fine layer of Nickel is deposited over another material.The purpose is to change the physical properties of the object, viz. its electrical conductivity, durability, performance, and appearance.Therefore, It adds brightness and luster to the object and is, used for decorative purposes. Also, it makes objects corrosion resistant as well as wear & tear-resistant.There are two types of nickel plating viz.Nickel electroplating: in this, the nickel layer is deposited through an electrolysis processElectroless nickel plating: In this, an autocatalytic reaction is used to do the same.

Nickel Electroplating

In nickel electroplating, Nickel is used as an anode while the object to be plated with Nickel is taken as a cathode.These two electrodes are immersed in an electrolyte such as nickel sulfate or nickel chloride and an electric current is applied using a DC power source as a rectifier.The flow of current results in the discharge of positively charged nickel ions at the cathode. This causes a thin layer of nickel to deposit on the surface of the object. As the anode slowly gets dissolved it is also known as the soluble anode.

Electroless Nickel Plating

The electroless nickel plating is comparatively simple. There is no need to pass an electric current rather the plating occurs due to an autocatalytic reaction.As a part of pre-treatment, the object to be plated is thoroughly cleaned and then activated using an acid etch.Thereafter, the material is coated with Nickel by immersing it in a reducing agent.When certain catalysts are added to this solution, they changes metal ions into metal causing them to deposit on the object’s surface. It is different from electroplating as it utilizes the process of chemical reduction instead of passing an electric current.

Benefits of Nickel Plating

Coating objects with a fine layer of Nickel improves their physical properties drastically. Also, there are many other benefits of nickel plating a few of them are given below:• It is used to enhance the value, utility, and appeal of an object.• The ‘silver’ coinage is mostly steel plated with nickel. It is appreciable due to its low cost and long life.• In the automotive industry, nickel is used for plating plastic and aluminum parts to improve aesthetics and durability.• Nickel plating is also important in the aerospace industry due to several important properties of nickel such as hardness, adhesion, corrosion and erosion resistance, etc.• It is used in electronic industries for coating components such as circuits, connectors, microprocessors, etc.

Properties of Nickel

A few important properties of nickel are given in the table below:

Uses of Nickel

Some of the important uses of nickel are listed below:• Being a good conductor of electricity nickel is used in making electrical wires.• Due to its high resistance to corrosion even under high temperatures, it is also used in making gas turbines and rocket engines.• Nickel is used for making a variety of alloys which are used for making many important products based on their abilities, for example, stainless steel is used for making utensils and other kitchen wares.• An alloy of copper and nickel, named Monal, is especially used for propeller shafts in desalination plants as well as boats and ships due to its high corrosion resistance in seawater.• Nickel is also used in making coins.• Nickel is ferromagnetic in nature. Readout the article on is Nickel magnetic.

Conclusion

Nickel does not rust. Rusting is the property of iron and its alloys due to which they oxidize to form a layer of loose powdery iron oxide which makes the object brittle and fragile.Nickel is highly resistant to corrosion. It withstands a wide range of temperatures, extremely humid conditions, and harsh chemicals.The Nickel’s face-centered cubic lattice structure is majorly responsible for its highly corrosion-resistant property.When exposed to severe settings for prolonged durations, Nickel corrodes and develops a green coating of nickel oxide on its surface known as Platina.Nickel plating is used to enhance the appearance, durability, and strength of a material.If you guys liked the article, share it in your circle and let me know if you have any doubts in the comments.Happy learning!!Does Tungsten Rust